Tel:+86-7103723830

Email:sales12@jhchemical.com

FAX:

FACTORY:No. 32, Tianshun Avenue, Xiangcheng Economic Development Zone, Xiangyang City, Hubei Province,China

Production Manager:Hank Yan

Tel:+86 13797738659

Sales Manager:Tiffany Yang

Tel:+86-13871702573

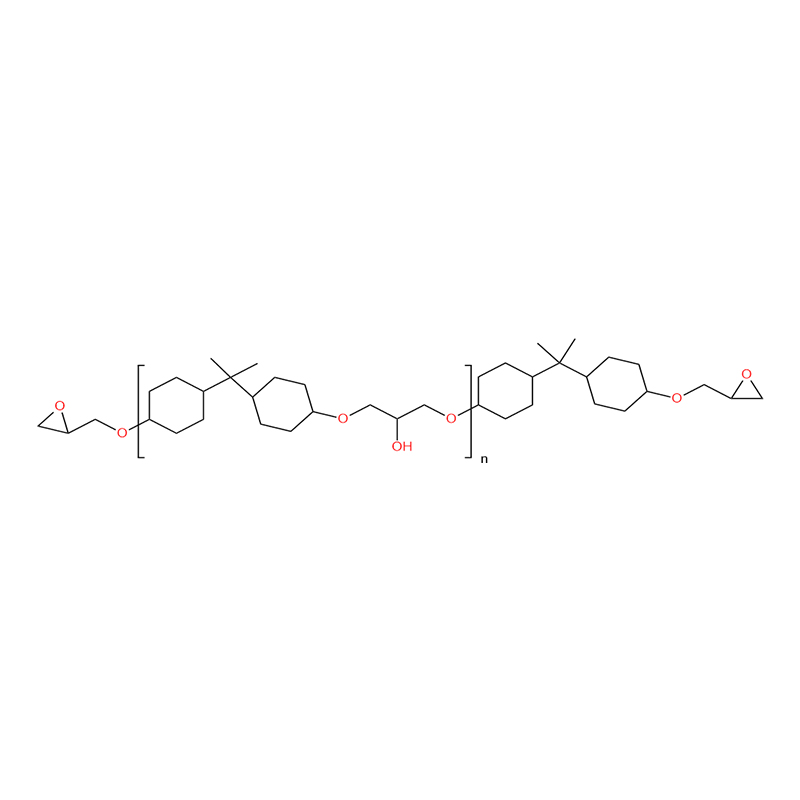

Epoxy resins are widely used in various industries due to their excellent mechanical, electrical, and thermal properties. Among the different types of epoxy resins, hydrogenated bisphenol A epoxy resin stands out for its unique characteristics and applications. In this article, we will discuss the cost factors associated with hydrogenated bisphenol A epoxy resin, including customization, production, distribution, and manufacturing.

Customization Costs

Customization is an essential aspect of the epoxy resin industry, as it allows manufacturers to tailor their products to meet specific customer requirements. The cost of customizing hydrogenated bisphenol A epoxy resin depends on various factors, such as the desired properties, application, and volume. Customization may involve modifying the chemical structure, molecular weight, or additives to achieve the desired performance. The cost of customization can range from a few cents to several dollars per pound, depending on the complexity of the modifications and the scale of production.

Production Costs

The production cost of hydrogenated bisphenol A epoxy resin is influenced by several factors, including raw materials, production processes, equipment, labor, and energy costs. Bisphenol A is the primary raw material used in the production of hydrogenated bisphenol A epoxy resin. The cost of bisphenol A varies depending on market conditions and supply chain dynamics. Additionally, the production process involves complex chemical reactions that require specialized equipment and skilled labor. The cost of production can range from $2 to $10 per pound, depending on the scale of production and the efficiency of the manufacturing process.

Distribution Costs

Distributing hydrogenated bisphenol A epoxy resin involves transporting the product from the manufacturer to the end-user or retailer. The cost of distribution includes transportation, handling, storage, and insurance. The cost of distribution can vary significantly depending on the distance between the manufacturer and the customer, the mode of transportation (e.g., truck, rail, sea), and the volume of goods shipped. The cost of distribution can range from a few cents to several dollars per pound, depending on the distance and mode of transportation.

Manufacturing Costs

Manufacturing costs refer to the expenses incurred by a company in producing its products. For hydrogenated bisphenol A epoxy resin manufacturers, manufacturing costs include raw material costs, labor costs, energy costs, maintenance costs, and overhead costs. The cost of manufacturing can vary significantly depending on the scale of production, the efficiency of the manufacturing process, and the level of automation. The cost of manufacturing can range from $2 to $10 per pound, depending on the scale of production and the efficiency of the manufacturing process.

In conclusion, the cost of hydrogenated bisphenol A epoxy resin is influenced by various factors, including customization, production, distribution, and manufacturing costs. The cost can range from a few cents to several dollars per pound, depending on the complexity of the modifications, the scale of production, and market conditions. As the demand for hydrogenated bisphenol A epoxy resin continues to grow in various industries, it is essential for manufacturers to optimize their production processes and distribution channels to maintain competitiveness in the market.